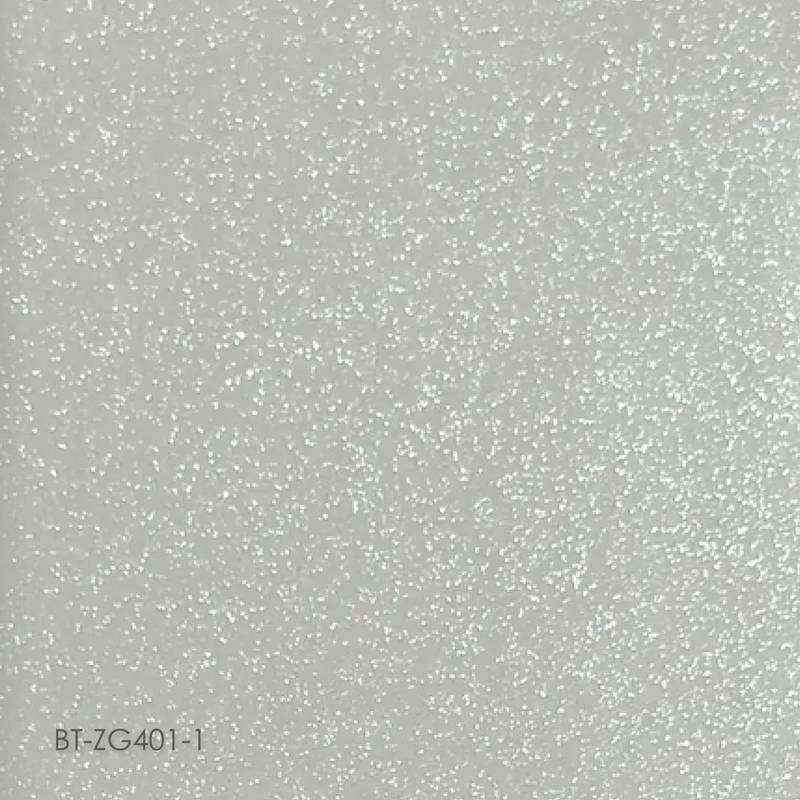

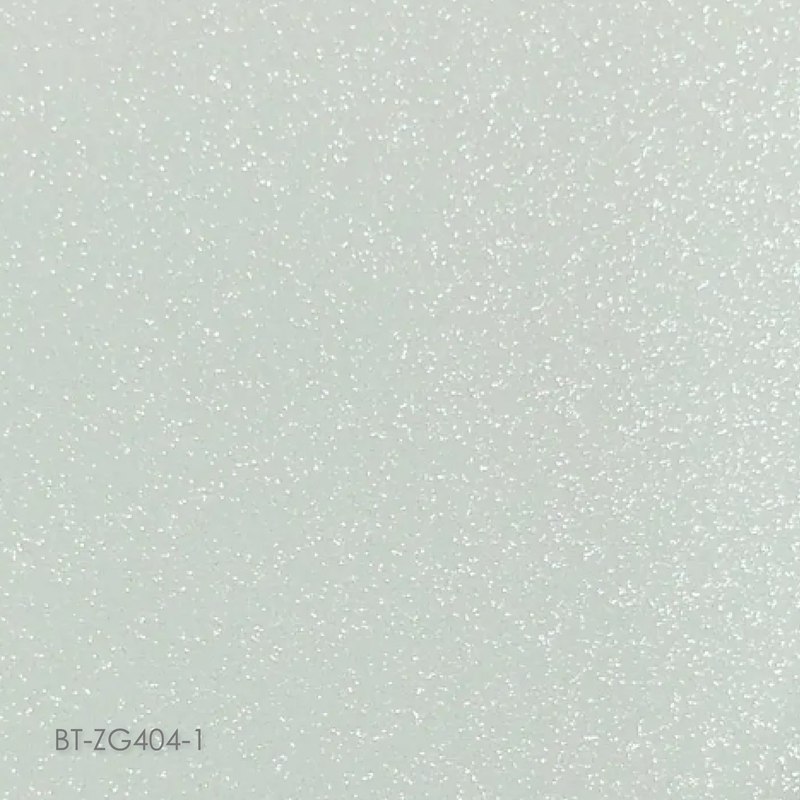

Glitter Lamination Film

Please click the button below to contact us.

Glitter Lamination Film is a decorative film with a shimmering, granular effect, widely used in a variety of applications requiring enhanced visual appeal. Made from a special, environmentally friendly material, its surface is dotted with tiny glitter particles, creating a unique shimmering effect under light, adding a luxurious and high-end visual quality to any surface.

Product Description

Glitter Lamination Film is a decorative film with a shimmering, granular effect, widely used in a variety of applications requiring enhanced visual appeal. Made from a special, environmentally friendly material, its surface is dotted with tiny glitter particles, creating a unique shimmering effect under light, adding a luxurious and high-end visual quality to any surface. Whether used for architectural decoration, furniture cladding, or other creative designs, Glitter Lamination Film provides a long-lasting and satisfying decorative effect.

Glitter Lamination Film Information:

Place of Origin: China

Usage: Laminate on panels

Logo: Accept Customized Logo

OEM/ODM: Availalbe

Packaging: Rolls

Transportation: Shippment

Application: Home or bussiness sapce decoration

Terms of Trade: T/T

Supply Capacity: Large supply

Quality/Safety Certification: SGS certification

Glitter Lamination Film Features:

1. Environmentally Friendly Materials

Glitter Lamination Film uses environmentally friendly PVC (polyvinyl chloride) as its base material, complying with multiple international environmental standards. Its production process eliminates the use of hazardous substances such as phthalates and heavy metals, ensuring safety for human health and the environment. The film has passed SGS Certification's environmental testing, with formaldehyde emissions below 0.1mg/L, significantly lower than the international standard of 0.5mg/L, meeting the stringent environmental requirements for interior decoration materials. This environmentally friendly material ensures safe use in a variety of indoor environments, without emitting harmful gases, protecting user health and environmental safety.

2. Color and Pattern Variety

Glitter Lamination Film offers a variety of color and pattern options to meet the individual needs of different users. Colors range from classic silver and gold to a variety of trendy colors, and patterns include fine glitter particles and large glitter spots. Each color and pattern is carefully designed to ensure optimal visual effects under varying lighting conditions. For example, in laboratory lighting tests, a certain silver glitter film achieved over 90% visibility at various angles, ensuring uniform and consistent decorative effects.

3. Chemical Stability

This film exhibits excellent chemical stability, maintaining color stability in various weather conditions and resisting fading. UV exposure testing showed a color change of only 2.3% after 500 hours of UV exposure, far below the industry standard of 5%. Furthermore, it exhibits excellent flexibility and exhibits no whitening when bent. After a 180-degree bend test, the film's surface retained its original gloss and color, showing no cracking or discoloration. This stability ensures that the decorative effect remains unchanged over long-term use, regardless of environmental factors.

4. Durability

Glitter Lamination Film exhibits excellent durability, resisting abrasion, scratches, humidity, corrosion, and high and low temperature environments. Its abrasion resistance reaches 8,000 revolutions (using the Taber abrasion test), far exceeding the industry standard of 3,000 revolutions. In humidity testing, the film showed no significant changes in physical properties or appearance after 96 hours in a high humidity environment (95% relative humidity). Furthermore, it exhibits excellent high and low temperature resistance, maintaining excellent flexibility and strength within a temperature range of -40°C to 80°C. This durability ensures the film maintains excellent condition in a variety of harsh environmental conditions, extending its service life.

5. High Sealing Properties

This film exhibits excellent sealing properties, with a near-zero gas permeability. It effectively blocks harmful gases released by various adhesives, coatings, and other materials, such as formaldehyde, benzene, and dioxins. In laboratory testing, when the film was applied to a formaldehyde-releasing material, formaldehyde permeability was less than 0.01mg/m² after 24 hours, demonstrating significant barrier effectiveness. This high sealing property provides additional protection for indoor environments, reducing the release of harmful gases and contributing to a healthier indoor environment.

6. Flame Retardant Properties

Glitter Lamination Film has undergone a special flame retardant treatment, giving it excellent fire resistance. It achieves UL94 V-0 flame retardancy, the highest level of flame retardancy for plastic materials. In flame tests, when a flame contacts the film's surface, it automatically extinguishes within 10 seconds, without any persistent burning or dripping. This flame retardancy complies with international fire protection standards and is suitable for use in various locations with stringent fire protection requirements, such as public spaces and commercial buildings.

7. Energy-Saving Properties

Glitter Lamination Film offers energy-saving properties during use. Its unique surface structure effectively reflects some light, reducing heat absorption indoors. Using this film in building exterior wall decoration can reduce air conditioning energy consumption. Experimental data shows that in high summer temperatures, exterior wall surfaces decorated with this film cool down by approximately 8°C and interior temperatures by approximately 3°C compared to unused walls, thereby reducing air conditioning use and energy consumption. Furthermore, its production process eliminates the need for complex chemical processes such as electroplating and painting, reducing energy consumption and environmental pollution.

8. Moderate Thickness

Glitter Lamination Film's standard thickness is 0.18mm. This thickness ensures excellent flexibility for easy application and installation, while also providing sufficient strength and durability. In practical applications, this thickness allows the film to easily conform to complex surfaces, such as curved furniture edges and irregular architectural decorative components, without adding excessive weight or bulk. During application, its excellent flexibility allows the film to adhere tightly to various substrates without wrinkling or bubbles, ensuring a flawless decorative effect.

Glitter Lamination Film Application:

1. Exterior Wall Decoration

In exterior wall decoration, Glitter Lamination Film is widely used in decorative wall panels and curtain wall systems. Its unique shimmering effect adds a luxurious and modern feel to a building's exterior, enhancing its overall visual appeal. In commercial building exteriors, walls decorated with this film create a uniform shimmering effect in sunlight, attracting the attention of passersby. After long-term outdoor testing, the film maintains its decorative effect and physical properties despite UV exposure, wind and rain, and other conditions. Its high sealing and flame retardant properties also meet building safety standards, providing additional protection for buildings.

2. Interior Decoration

In interior decoration, this film is commonly used for ceiling, wall, and door panel decoration. Its diverse color and pattern options cater to diverse decorating styles, adding a unique decorative touch to interior spaces. In high-end residential interiors, ceilings decorated with Glitter Lamination Film create a soft shimmering effect under lighting, enhancing the sense of luxury and warmth. Furthermore, its easy-to-clean surface makes daily maintenance simple and convenient; simply wipe with a damp cloth regularly to maintain a clean and shiny surface.

3. Furniture Veneer

Glitter Lamination Film is an ideal veneer material for the furniture manufacturing industry. Its wide selection of colors and patterns creates a unique visual effect for furniture, enhancing its quality and appeal. In tests conducted by furniture manufacturers, furniture veneered with Glitter Lamination Film maintained its decorative effect after five years of use, showing no signs of wear, fading, or peeling. Its excellent adhesion and durability ensure it resists damage from friction and impact during daily use, providing a positive user experience. Furthermore, its waterproof and moisture-resistant properties make it suitable for a variety of furniture types, such as dining tables and coffee tables, extending the lifespan of the furniture.

4. Display Design

In the display design field, this film is widely used in the decoration of exhibition booths, display racks, and showcases. Its unique shimmering effect attracts audience attention, enhancing display quality and brand influence. At international exhibitions, booths decorated with Glitter Lamination Film created a dazzling visual effect under lighting, attracting numerous visitors. A follow-up survey of multiple booths found that visitors to booths decorated with this film stayed an average of 30% longer during the exhibition, effectively enhancing both the presentation and brand promotion. Its ease of processing and installation also made exhibition setup more efficient and convenient, saving time and costs.

5. Automotive Decoration

In the automotive decoration sector, Glitter Lamination Film is used for both body wraps and interior decoration. Its excellent durability and unique decorative effects enhance the overall appearance and personalization of a car. In tests conducted at a car detailing center, cars covered with this film maintained their decorative effects after three years of outdoor use, showing no signs of fading, wear, or warping. Its high sealing properties effectively prevent moisture and dust from entering the vehicle body, protecting the paint from damage. Furthermore, its flame retardant properties meet automotive interior safety standards, ensuring a safe interior environment. Furthermore, its easy-to-clean surface keeps cars looking pristine during daily use, requiring only regular wiping with a damp cloth to remove dust and stains.

6. Gift Packaging

This film is an ideal decorative material for gift packaging. Its gorgeous shimmering effect elevates the quality and appeal of gifts, making it a suitable packaging option for high-end gifts. In luxury brand packaging applications, gift boxes made with Glitter Lamination Film create a dazzling visual effect under light, enhancing the gift's visual appeal and added value. Its excellent foldability and adhesion make the packaging process more convenient and efficient, eliminating the need for complex processes and equipment to create exquisite gift packaging, meeting the demands of high-end gift packaging.

Glitter Lamination Film Maintenance:

1. Daily Cleaning

To maintain the surface cleanliness and decorative effect of Glitter Lamination Film, regular daily cleaning is recommended. Gently wipe the film surface with a soft, clean, damp cloth to remove dust and stains. Avoid using harsh cleaning tools, such as steel wool or scouring pads, to avoid scratching the film surface. A neutral detergent diluted in a 1:20 ratio with water can be used. Gently wipe the film with a damp cloth, then rinse thoroughly with clean water and wipe dry. Experiments have shown that after cleaning with a neutral detergent, the gloss retention rate of the film surface can reach over 95%, ensuring the long-lasting decorative effect. A thorough cleaning is recommended once a week, and more frequent cleaning may be appropriate in areas with high traffic or heavy contamination.

2. Avoid scratches with sharp objects

When using and storing Glitter Lamination Film, avoid scratching the film surface with sharp objects. For example, avoid direct contact of hard objects such as keys and coins with the film surface to avoid scratches. If heavy objects need to be placed on the film surface, it is recommended to place a soft material, such as a rubber mat or foam pad, between the object and the film to distribute the pressure and reduce impact on the film surface. Laboratory scratch tests using a 3H hardness pencil showed that scratch depth on films protected by soft pads was only 10% of that on unprotected films, effectively preserving the decorative effect. Additionally, during installation, avoid cutting or trimming with sharp tools. It is recommended to use specialized cutting tools and exercise caution when handling.

3. Moisture and Waterproofing

Although Glitter Lamination Film has excellent durability, it still requires protective measures in environments with high humidity or water immersion. Avoid prolonged exposure to rain or humidity to prevent moisture from penetrating between the film and the substrate, potentially weakening the bond or damaging the substrate. For outdoor use, it is recommended to apply a clear protective lacquer to the film surface to enhance its water resistance. Experimental data shows that after 30 days of water immersion testing, the film coated with protective paint showed no significant changes in its physical properties and decorative effect, while the uncoated film exhibited slight bubbling and peeling. When used indoors, the ambient humidity should be maintained between 30% and 70% to prevent condensation on the film surface.

4. Avoid high-temperature environments

Glitter Lamination Film may deform or discolor in high-temperature environments. Therefore, it should be avoided from prolonged exposure to high temperatures, such as direct sunlight or near heat sources. During high summer temperatures, it is recommended to use sunshades, such as awnings or curtains, to reduce the film surface temperature. Experiments have shown that after 72 hours of continuous exposure to a temperature of 60°C, the unprotected film showed slight deformation and fading, while the film with sunshades remained intact. Furthermore, in vehicle interior applications, the film should be avoided from prolonged exposure to high temperatures near the dashboard; if necessary, use thermal insulation materials for protection.

5. Regular Inspection

Regularly inspect the surface and adhesion of the Glitter Lamination Film to ensure long-term stability. This inspection should include any scratches, bulges, or peeling, as well as the strength of the bond between the film and the substrate. A comprehensive inspection is recommended quarterly, and any issues found should be promptly repaired. For example, for small scratches or bulges, use a specialized repair glue, following the product instructions, to ensure the finished finish matches the surrounding area. For larger areas of peeling, contact a professional for immediate evaluation and repair to prevent further damage, which could affect the film's lifespan and decorative effect.