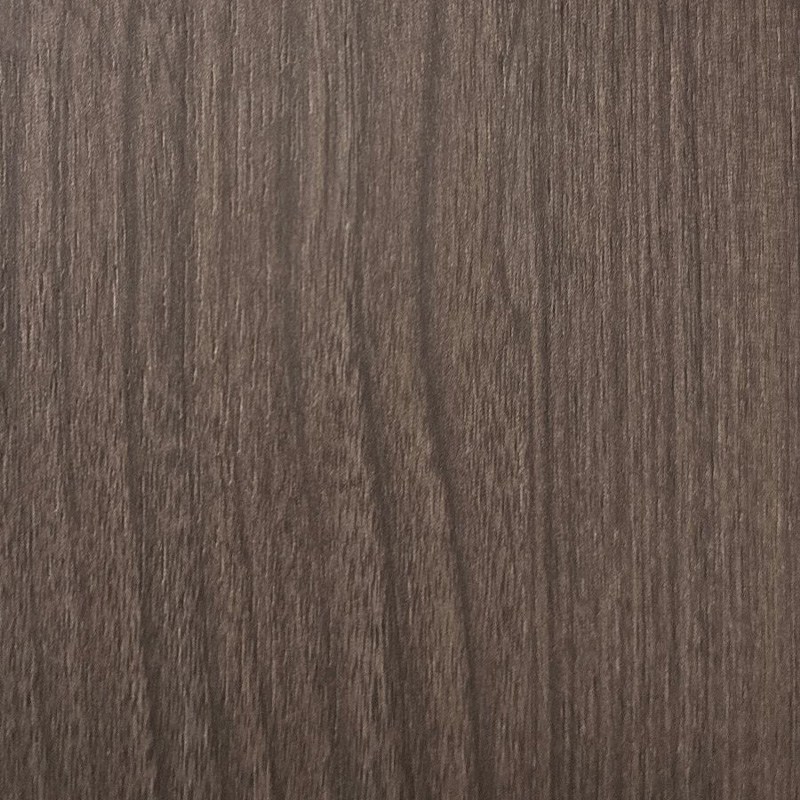

High Quality Wood Grain Overlay

Please click the button below to contact us.

Wood Grain Overlay is a decorative film with a wood grain effect, primarily used for surface decoration and protection. Made from high-quality, environmentally friendly materials, it simulates the grain and texture of real wood, providing a natural, aesthetically pleasing appearance for a variety of products.

Product Description

Wood Grain Overlay is a decorative film with a wood grain effect, primarily used for surface decoration and protection. Made from high-quality, environmentally friendly materials, it simulates the grain and texture of real wood, providing a natural, aesthetically pleasing appearance for a variety of products. This film offers a refined visual and tactile experience, while its durability and easy-to-clean properties simplify maintenance. This film is widely used in furniture, architecture, home decor, and other fields, providing users with a permanent decorative solution.

Wood Grain Overlay Features:

1. Environmentally Friendly Materials

Wood Grain Overlay utilizes high-quality PVC (polyvinyl chloride) as its base material, complying with multiple international environmental standards. Its production process eliminates the use of hazardous substances such as phthalates and heavy metals, ensuring safety for human health and the environment. The film has passed SGS Certification's environmental testing, with formaldehyde emissions below 0.1mg/L, significantly lower than the international standard of 0.5mg/L, meeting the stringent environmental requirements for interior decoration materials. This environmentally friendly material ensures safe use in a variety of indoor environments, without emitting harmful gases, protecting user health and environmental safety.

2. Wood Grain Effect

Wood Grain Overlay can simulate the textures of a variety of natural woods, such as oak and walnut. The clarity and detail of the wood grain pattern are industry-leading. Through high-precision printing technology, the wood grain pattern achieves a resolution of up to 1200dpi, resulting in a more realistic-looking texture. Color stability has been tested and shows a color change of less than 3% under UV (ultraviolet) light, ensuring no noticeable fading or discoloration after long-term use. This realistic wood grain effect not only enhances the product's aesthetics but also makes the film a perfect substitute for real wood in a variety of decorative applications, conserving resources while providing more stable performance.

3. Durability

The film exhibits excellent abrasion resistance, achieving 10,000 cycles (using the Taber abrasion test), far exceeding the industry standard of 5,000 cycles. Its impact strength reaches 50 J/m, effectively withstanding the accidental bumps and impacts of daily use. Furthermore, it exhibits excellent chemical resistance, resisting common cleaning agents, oils, and acids and bases. After immersion in 10% hydrochloric acid and sodium hydroxide solutions for 24 hours, it showed no noticeable damage or discoloration. This durability ensures the film maintains its excellent appearance and performance over long-term use, reducing maintenance and replacement costs.

4. Moderate thickness

The standard thickness of Wood Grain Overlay is 0.2mm, which is designed to be flexible, easy to construct and install, and strong and durable. In practical applications, this thickness of film can easily adapt to various complex surfaces, such as curved furniture edges and irregular architectural decorative parts, without adding too much weight or volume. This thickness of film can perfectly fit various curved surfaces during construction without wrinkles or bubbles, ensuring the perfect presentation of decorative effects.

5. Material compatibility

The film has good material compatibility and can be perfectly combined with a variety of common building materials and furniture materials. It can be applied to the surfaces of materials such as particleboard, medium-density fiberboard (MDF), metal and glass, providing excellent adhesion and decorative effects. When combined with particleboard, its adhesion test (using ASTM D3359 standard) results show that the adhesion level reaches 5B, ensuring that the film will not peel or delaminate during long-term use. This good material compatibility enables the film to perform excellently in various application scenarios.

6. Safety Performance

Wood Grain Overlay has excellent flame retardancy, meeting the UL94 flame retardant standard and effectively reducing fire risks. In experiments, when flames contacted the film's surface, the flame propagation rate was less than 0.1 m/min, meeting flame retardant requirements for building materials. Furthermore, its surface hardness reaches 2H (pencil hardness), effectively resisting scratches and abrasions from daily use, ensuring long-term safety and aesthetics. These flame-retardant and wear-resistant properties make the film a reliable safety feature in a variety of public spaces and domestic environments.

7. Exquisite Craftsmanship

Advanced printing and laminating processes ensure the accuracy and consistency of the wood grain pattern. With a printing accuracy of ±0.1mm, the pattern's repeatability and alignment are extremely high, resulting in a harmonious and aesthetically pleasing overall effect when applied over large areas. Furthermore, the lamination process utilizes high-temperature and high-pressure technology, achieving an interlayer bond strength exceeding 1.5 MPa, ensuring the film will not delaminate or peel over time. This sophisticated craftsmanship not only enhances product quality but also ensures the film maintains stable performance and an aesthetically pleasing appearance in a variety of challenging environments.

8. Easy Cleaning and Maintenance

The Wood Grain Overlay's surface undergoes a special treatment for excellent stain resistance. Its contact angle reaches 85°, allowing water and oil to bead up and roll off the surface without leaving residue. Stains and dust can be easily removed with a mild detergent and a damp cloth. Tests have shown that even after 100 wipes with common detergents, the surface retains over 95% of its gloss and clarity, ensuring long-term aesthetics and hygiene. This easy-to-clean feature ensures the film maintains its excellent appearance in a variety of environments, reducing maintenance effort and costs.

Wood Grain Overlay Application:

1. Furniture Manufacturing

In the furniture manufacturing sector, Wood Grain Overlay is a highly valuable decorative material. It is widely used in a variety of furniture products, such as cabinets, wardrobes, desks, and headboards. In cabinet manufacturing, the film provides cabinet doors and drawers with a natural wood grain appearance while offering excellent abrasion and chemical resistance. A typical cabinet door retains its gloss and integrity through prolonged opening and closing, as well as daily cleaning, without scratching or fading. Tests have shown that desks coated with the film retained over 95% of their gloss after 2,000 rub tests, demonstrating its exceptional durability. This allows furniture manufacturers to produce products that are both aesthetically pleasing and durable, meeting consumer demand for high-quality furniture while enhancing their market competitiveness.

2. Architectural Decoration

In architectural decoration, Wood Grain Overlay is suitable for wall, ceiling, and floor decoration. Its environmentally friendly nature and flame retardant properties meet building safety standards, making it an ideal choice for interior decoration. In wall decoration, this film not only creates a rich wood grain pattern but also effectively resists the scratches and stains of everyday use. For example, in hotel lobbies or office building wall decoration, it can withstand frequent foot traffic and cleaning while maintaining a beautiful decorative effect. In floor decoration, this film exhibits excellent abrasion and compression resistance, capable of withstanding foot traffic and the pressure of heavy objects. Test data shows that its wear resistance reaches 15,000 revolutions, far exceeding the industry standard, ensuring that the floor remains in good condition over long-term use and adding a natural and warm wood feel to architectural spaces.

3. Home Decoration

Home decoration is another important application area for Wood Grain Overlay. It is widely used to decorate picture frames, curtain boxes, skirting boards, and other home accessories. In picture frame decoration, this film can simulate the grain of real wood, adding a natural and elegant appearance to the frames. Due to its flexibility and easy processing, it can be perfectly adapted to frames of various shapes and sizes, ensuring a perfect decorative effect. In curtain box decoration, the film can effectively block the curtain track, adding a sense of hierarchy and beauty to the space. Its easy-to-clean properties allow the curtain box to be wiped with a damp cloth regularly in daily use to remove dust and stains, keep it clean and tidy, and create a warm and natural atmosphere for the home environment.

4. Car interior

In the automotive manufacturing industry, the film is used to decorate car interior parts such as dashboards, center consoles, door interior panels, etc. In the center console decoration, it not only provides a beautiful wood grain effect, but also withstands the test of temperature changes and direct sunlight in the car. Tests show that after 500 hours of ultraviolet radiation, the color difference change rate of the film is only 1.2%, which is far lower than the industry standard of 5%. This stability makes it an ideal choice for improving the quality and beauty of car interiors. At the same time, the easy-to-clean properties of the film allow car owners to easily remove stains and dust in the car during daily use, keep the interior clean and beautiful, and extend the service life of the interior.

5. Office Furniture

This film's durability and easy-to-clean properties make it an ideal choice for office furniture such as desks, filing cabinets, and conference tables. Desks frequently come into contact with various office supplies and cleaning agents during daily use, and this film effectively resists these substances, maintaining a clean and beautiful surface. Testing has shown that desks treated with this film retained over 90% of their gloss after 1,000 cleaning cycles, demonstrating its exceptional durability.

6. Gift Packaging

In the gift packaging sector, this film can be used to create high-end gift boxes and packaging materials. Its exquisite wood grain effect enhances the quality and appeal of gifts, making it a suitable packaging option for high-end gifts. For example, in jewelry gift boxes, this film not only provides an aesthetically pleasing appearance but also offers excellent water and moisture resistance, effectively protecting gifts from environmental factors and ensuring their quality and integrity during delivery. Furthermore, the film's ease of processing makes the packaging process more convenient, reducing production costs and improving efficiency.

Wood Grain Overlay Maintenance:

1. Daily cleaning

It should be done regularly. It is recommended to use a soft damp cloth or sponge to gently wipe the surface of Wood Grain Overlay to remove dust and stains. Avoid using rough cleaning tools such as steel wool or scouring pads, as these tools may scratch the surface of the film, affecting its gloss and aesthetics. For stubborn stains, a neutral detergent can be used. When using, dilute the detergent with water in a ratio of 1:10 and wipe it, then rinse it with clean water and wipe it dry. Regular cleaning can maintain the gloss and clarity of the film and extend its service life. It is generally recommended to perform a comprehensive cleaning once a week to ensure that the film is always in good condition.

2. Avoid scratches from sharp objects

During use, be sure to avoid sharp objects directly contacting the surface of the film. Knives, pointed tools, nails, etc. may scratch the film, leaving marks that are difficult to repair. In addition, if you need to place heavy objects on the surface of the film, it is recommended to use soft gaskets, such as rubber pads or cloth pads, to isolate the heavy objects from direct contact with the film, thereby dispersing the pressure and reducing the risk of scratches. When transporting or moving furniture, extreme care should be taken to avoid scratching the film surface with sharp corners or edges. These measures can effectively protect the film's integrity and maintain its aesthetic appearance.

3. Prevent Chemical Attack

Prolonged contact of the film with chemicals such as strong acids, strong bases, or organic solvents should be avoided. These substances may react with the film, causing discoloration, dissolution, or damage. Common hazardous chemicals include, but are not limited to, disinfectants, alcohol, vinegar, detergents, and herbicides. If the film accidentally comes into contact with these chemicals, immediate action should be taken. First, flush the contaminated area with plenty of water to dilute and flush away the chemical. Next, rinse with a neutral detergent to ensure that any residual chemical is completely removed. Finally, rinse again with clean water and wipe dry. This process minimizes chemical damage to the film.

4. Regular Inspection

Regular inspection of the film surface is an important part of maintenance. Carefully inspect the film surface for signs of bulging, lifting, or delamination. These may be caused by temperature fluctuations, humidity changes, external impact, or other factors. If these problems are found, timely measures should be taken to repair them. For small areas of bulging or edge lifting, special repair glue can be used for treatment. When using repair glue, follow the product instructions to ensure that the glue is evenly applied to the damaged area and keep the environment clean and stable during the drying process of the glue. Regular inspections and timely repairs can prevent small problems from turning into big problems and extend the service life of the film.

5. Avoid high temperature exposure

Wood Grain Overlay should be kept away from high temperature or direct sunlight for a long time as much as possible. High temperature and ultraviolet radiation may cause film aging, discoloration, brittleness and other problems. In the hot summer, both indoor and outdoor temperatures may rise, so protective measures need to be taken. Indoors, sunshades, blinds or thermal insulation films can be used to block some sunlight and heat. Outdoors, items should be placed in the shade as much as possible to avoid direct sunlight. These measures can effectively reduce the risk of damage to the film by high temperature and ultraviolet rays and maintain the performance and appearance of the film.

6. Professional maintenance

For large-scale damage or problems that are difficult to repair, it is recommended to contact professional maintenance personnel for processing. Professional maintenance personnel possess extensive experience, specialized equipment, and materials, enabling them to provide high-quality repair services. Before any professional maintenance is performed, it's important to thoroughly discuss the problem with the technician, detailing the nature, scope, and timing of the problem. This will help the technician prepare in advance and develop an appropriate repair plan. Professional maintenance ensures the film's appearance and performance are restored to the greatest extent possible, providing a superior solution for the user.