Environmental Friendly Wood Effect Film

Please click the button below to contact us.

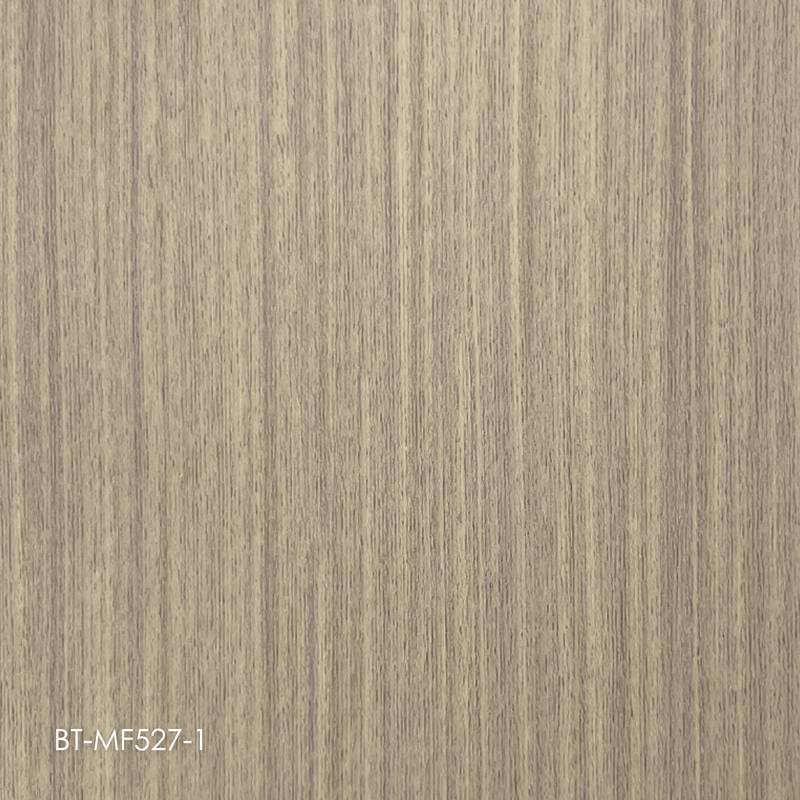

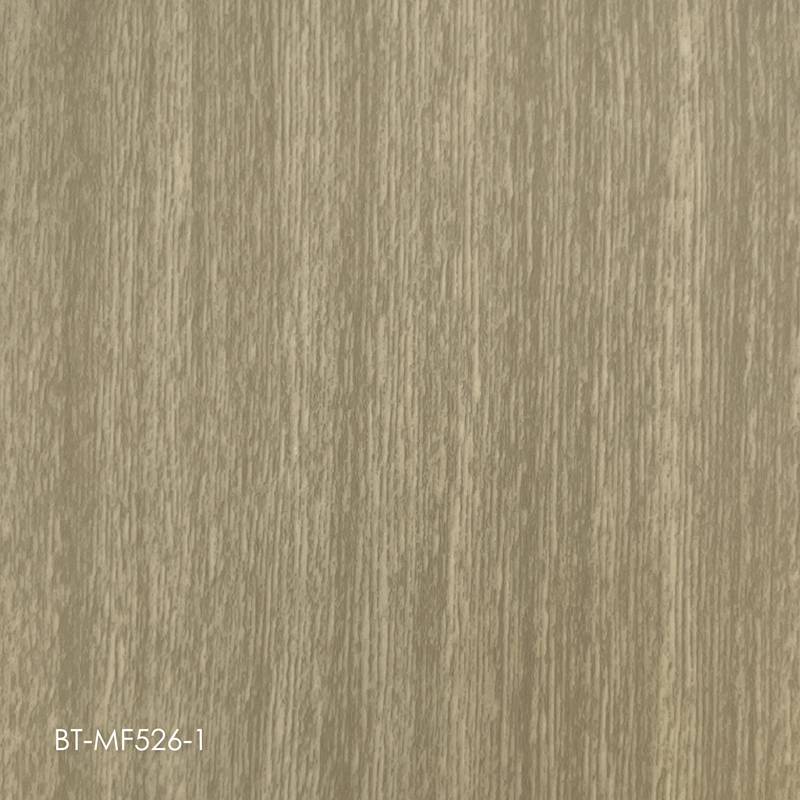

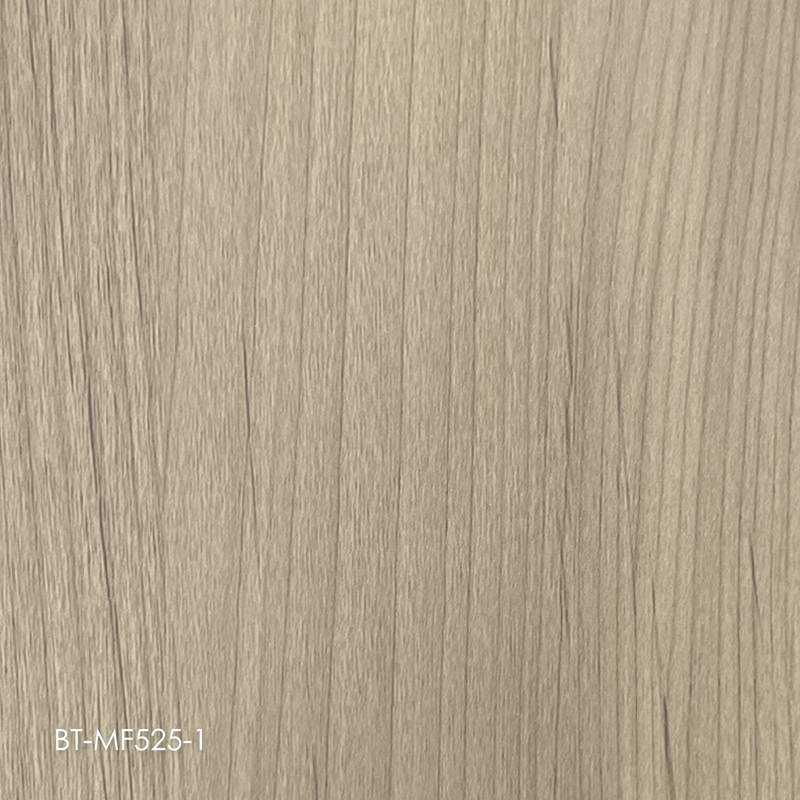

Wood Effect Film is a PET film with a wood effect designed for a variety of decorative applications. This film presents realistic wood grain patterns and natural colors, adding a warm and natural atmosphere to any space.

Product Description

Wood Effect Film is a PET film with a wood effect designed for a variety of decorative applications. This film presents realistic wood grain patterns and natural colors, adding a warm and natural atmosphere to any space. This film not only provides a real wood look, but also has the advantages of easy installation, durability and convenient maintenance. Whether used for wall decoration, furniture veneer or other decorative projects, Wood Effect Film can provide users with a beautiful and practical solution to create a comfortable and warm environment.

Wood Effect Film Information:

| Place Of Origin: | China |

| Usage: | Laminate On Panels |

| Logo: | Accept Customized Logo |

| OEM/ODM: | Availalbe |

| Packaging: | Rolls |

| Transportation : | Shippment |

| Application: | Home Or Bussiness Sapce Decoration |

| Terms Of Trade: | T/T |

| Supply Capacity : | Large Supply |

| Quality/Safety Certification: | SGS Certification |

| Factory Nature: | China Manufacturers Suppliers Factory |

Wood Effect Film Features:

PET material advantages

Wood Effect Film is made of PET material and has excellent comprehensive performance. The tensile strength of PET material can reach 60-70 MPa, which is 2-3 times that of ordinary plastics, and can withstand large external forces without breaking easily. At the same time, its elastic modulus is 2000-3000 MPa, which gives the film good flexibility and resilience. After testing, the PET film can still maintain more than 80% of its original strength after repeated folding 1000 times, providing a reliable material guarantee for decorative panels.

Precise thickness specifications

The thickness of this film is commonly found in 200-350μm, which is suitable for a variety of decorative applications such as wood grain furniture film. Films in this thickness range can provide good mechanical strength and durability while maintaining a certain degree of flexibility for easy installation and processing. Compared with thinner decorative materials, Wood Effect Film with a thickness of 200-350μm performs well in wear and impact resistance, which can effectively extend the service life of the decoration. Experimental data shows that after more than 5,000 friction tests, the surface of this thickness of film can still maintain a clear wood grain pattern without obvious signs of wear.

Width and roll length standard

Wood Effect Film provides standard width and roll length specifications, such as 1220mm×50m, to ensure the versatility and ease of use of the product. This combination of width and roll length can meet the needs of most decoration projects and reduce splicing and waste. At the same time, the manufacturer strictly controls the dimensional accuracy during the production process to ensure the flatness and dimensional stability of the film. User feedback shows that this standard specification of film can effectively cover a large area of decorative surfaces in practical applications, improve construction efficiency and reduce installation costs.

Matte surface treatment

The surface of Wood Effect Film is matte treated, and the gloss is stable at 15 ± 3 GU. This matte surface not only improves visual comfort, but also gives the space a soft and natural beauty. Compared with high-gloss materials, matte surfaces can better hide fine scratches and fingerprints, and are easier to maintain, providing users with a long-lasting and beautiful visual experience. In actual tests, the matte surface of Wood Effect Film performed well during use and maintained a good appearance even in high-frequency touch and use areas.

Easy-fit bubble-free technology

The film has excellent lamination performance and is easy to install without bubbles. Its electrostatic lamination technology ensures a close fit between the film and the substrate, avoiding the bubble problem common in the traditional film lamination process. In actual installation, just lay the film flat on the clean and dry substrate surface, and then use a scraper to gently scrape it flat to achieve a perfect fit without bubbles. Experimental data shows that the edge lift rate of Wood Effect Film laminated using this technology is less than 2%, ensuring the flatness and durability of the decorative effect, providing users with a professional-level installation experience.

Excellent weather resistance

Wood Effect Film has excellent weather resistance and can withstand the test of various environmental conditions. It has excellent water resistance, with a water contact angle of up to 110° - 115°, which can effectively prevent moisture from penetrating into the substrate. In actual tests, after the film was soaked in water for 72 hours, there was no water absorption or swelling on the surface. At the same time, it has excellent scratch resistance and a surface hardness of 3H (pencil hardness standard), which can effectively resist scratches and wear in daily use. After 500 hours of UV aging test, the ΔE value of the wood grain pattern and color change of the film is less than 1.5, which is much lower than the industry standard requirement of ΔE less than 3.0, ensuring that the film always maintains good appearance and performance in long-term use, especially in indoor and outdoor environments.

Wide heat resistance range

Wood Effect Film has good heat resistance and can remain stable in a wide temperature range. Its long-term use temperature range is - 40℃ to 80℃, and it can withstand temperatures up to 120℃ for a short time. This wide heat resistance range enables the film to be used in various climates, whether in the cold northern region or the hot southern region, and it can maintain good physical properties and decorative effects. For example, in extremely high temperature environments, the film will not soften, deform or fade; in low temperature environments, it will not become brittle or crack, ensuring the long-term stability of the decoration.

Environmental protection and sustainability

PET material has good environmental properties and meets the environmental protection standards of interior decoration materials. Wood Effect Film adopts solvent-free process in the production process and does not contain harmful substances such as formaldehyde, benzene and other volatile organic compounds (VOC). According to the test of professional institutions, its formaldehyde emission is lower than the detection limit, only 0.03mg/m³, which is far lower than the national formaldehyde emission limit standard for interior decoration materials (0.1mg/m³). Use in children's rooms, elderly rooms and places with extremely high environmental protection requirements can provide a healthy and safe living environment for the family, allowing users to enjoy beautiful decoration without worrying about indoor air quality issues.

Wood Effect Film Application:

Decorative films are widely used in the following scenarios due to their rich textures, diverse colors and excellent anti-fouling properties:

Home wall decoration

Wood Effect Film is an ideal choice for home wall decoration. Its realistic wood grain pattern and natural color can create a warm and natural visual effect for the wall, enhancing the texture and atmosphere of the entire space. In practical applications, laminating the film on the wall decoration panel can easily achieve a wallpaper-like decorative effect, but compared with traditional wallpaper, it has better durability and waterproof performance. For example, in the wall decoration of the living room, choosing Wood Effect Film can make the wall present the texture of natural wood grain, enhance the layering and warmth of the space. At the same time, its matte surface treatment can effectively reduce light reflection, avoid glare interference when watching TV or reading, and provide residents with a comfortable and natural living environment.

Commercial space wood decoration

In commercial spaces, Wood Effect Film can be widely used in wooden decorative elements, such as wooden walls in hotel lobbies, wooden partitions in restaurants, etc. Its realistic wood grain effect and natural color can enhance the grade and taste of the space and create a high-end, natural commercial atmosphere. For example, using Wood Effect Film on the wooden walls of the hotel lobby can complement the luxurious chandeliers, exquisite decorations and other elements, showing the hotel's grade and taste. Compared with traditional wood decorative materials, PET film is easier and faster to install, and has good durability and easy maintenance. It can maintain a good decorative effect for a long time and reduce the hotel's maintenance costs and time.

Office furniture veneer

Wood Effect Film is suitable for veneer of office furniture, adding a natural and warm atmosphere to the office space. In practical applications, laminating the film on the surface of furniture such as desks, filing cabinets, and conference tables can effectively protect the furniture from scratches, wear and stains, while improving the beauty and texture of the furniture. Compared with the surface of ordinary office furniture, furniture decorated with Wood Effect Film is more durable and beautiful, providing employees with a comfortable and efficient working environment. For example, in a modern office, office furniture decorated with Wood Effect Film can be integrated with the overall decoration style to create a professional and natural working atmosphere.

Retail Store Display Area Decoration

In the display area of a retail store, Wood Effect Film can be used to decorate display racks and background walls to enhance the display effect of goods. Its natural wood grain pattern and warm tones can add a sense of closeness to nature to the display area, making the goods more attractive when displayed. For example, in the display area of a clothing brand, decorating Wood Effect Film on display racks and background walls can create a natural and warm shopping environment that complements the style of the clothing and stimulates customers' desire to buy. At the same time, its good durability and easy cleaning properties allow the display area to remain clean and beautiful for a long time, providing customers with a comfortable shopping experience.

Hotel Wood Decorative Elements

Wood Effect Film can play a unique role in the hotel's wooden decorative elements, such as wooden doors and wooden decorative lines. Its realistic wood grain effect and natural color can be integrated with the hotel's overall decoration style, enhancing the warmth and natural atmosphere of the space. For example, using Wood Effect Film on the hotel's wooden doors can make the door look closer to real wood, improving the hotel's decorative quality and customer experience. Compared with traditional wood decorative materials, PET film is easier and faster to install, and has good durability and easy maintenance. It can maintain good decorative effects for a long time and reduce the maintenance cost and time of the hotel.

Architectural wooden decorative elements

In the wooden decorative elements of buildings, such as wooden decorative panels on the facade of the building, wooden decorative walls at the entrance, etc., Wood Effect Film can provide a unique decorative solution. Its realistic wood grain pattern and natural color can add a natural and warm appearance to the building, enhancing the overall image and appeal of the building. For example, using Wood Effect Film to decorate wooden decorative panels on the facade of a modern building can be integrated with the glass curtain wall and other modern elements of the building to create a unique visual effect and attract the attention of pedestrians. At the same time, its good weather resistance and durability enable it to withstand the test of the outdoor environment for a long time, maintaining the stability and beauty of the decorative effect.

How to maintain Wood Effect Film:

Proper maintenance can greatly extend the service life of decorative films and avoid bubbling, fading and scratches. The following is a specific maintenance guide:

Daily cleaning and maintenance

In order to maintain the good appearance and performance of Wood Effect Film, daily cleaning is essential. It is recommended to use a soft, clean, dust-free cloth to gently wipe the surface of the film to remove dust and stains. If there are stubborn stains on the surface of the film, you can use a small amount of neutral detergent (such as detergent dilution) to wipe it, then wipe off the detergent residue with a clean damp cloth, and wipe it dry with a dry cloth. Avoid using rough cleaning tools or detergents containing abrasive ingredients to avoid scratching the matte surface of the film. Experimental data shows that the surface gloss and color saturation of the film that has been properly cleaned can remain stable for a long time, while the surface gloss of the film that has not been cleaned or used improper cleaning methods will gradually decrease, affecting the decorative effect. For example, in home wall decoration, regular cleaning can keep the film in good decorative effect and extend its service life.

Avoid contact with sharp objects

In daily use, try to avoid contact between Wood Effect Film and sharp objects, such as nails, keys, coins, etc. Sharp objects may leave scratches on the surface of the film, destroying its wood grain pattern and beauty. If you need to write or install other items on the film surface, it is recommended to use special writing tools or adopt a traceless installation method. For example, in the veneer decoration of office furniture, using a soft-tipped marker or removable stickers, and avoiding the use of hard nibs or permanent stickers, can effectively reduce the occurrence of scratches. Once a slight scratch is found on the surface of the film, it can be treated with a special film repair agent to restore its surface integrity. For deeper scratches, it is recommended to replace the film in time to maintain a good decorative effect and performance.

Temperature and humidity control

The performance and appearance of Wood Effect Film will be affected by the ambient temperature and humidity. In order to ensure the best condition of the film, the temperature and humidity of its use and storage environment should be controlled within an appropriate range. Generally speaking, the temperature should be maintained at 15-30℃, and the relative humidity should be maintained at 40%-60%. In a high temperature and high humidity environment, the film may absorb moisture, resulting in water spots on the surface or performance degradation; in a low temperature and dry environment, the film may become brittle and hard, and prone to cracks. The indoor temperature and humidity can be adjusted by using equipment such as air conditioners, dehumidifiers or humidifiers to create a stable environmental condition for the film. For example, in the home environment of humid areas in the south, especially in the rainy season, turning on the dehumidifier can effectively prevent the film from getting damp and maintain its good physical properties and decorative effects.

Regular inspection and repair

Regular inspection of Wood Effect Film is the key to ensure its long-term use. Every once in a while, carefully check whether there are scratches, wear, fading or other signs of damage on the surface of the film, and check whether the bonding parts between the film and the substrate are firm, and whether there are bubbling, degumming and other problems. If problems are found, timely measures should be taken to repair or replace them. For example, in home wall decoration, a quick inspection once a month and a detailed inspection once a quarter can timely discover and deal with potential problems to prevent problems from expanding. In the case of bubbling or degumming, special glue and tools can be used for re-pasting; for serious damage that cannot be repaired, a new film should be replaced in time to maintain the integrity and beauty of the wall decoration.

Avoid chemical corrosion

When using Wood Effect Film, avoid long-term contact with chemicals, such as acids, alkalis, oils, organic solvents, etc. If you accidentally come into contact with these chemicals, you should immediately rinse with plenty of water and wipe dry with a clean cloth. Experiments show that when the film is immersed in common organic solvents such as acetone for 5-10 minutes, the film surface will show obvious dissolution and damage. Therefore, during cleaning and maintenance, special attention should be paid to the ingredients of the detergents used, and cleaning products containing strong corrosive chemicals should be avoided. In places such as kitchens and bathrooms that are easily exposed to oil and detergents, more attention should be paid to preventing chemicals from eroding the film to ensure that it can play a decorative and protective role in a long-term and stable manner.

Professional maintenance guidance

For some complex maintenance issues or large-scale decoration projects, it is recommended to seek guidance and help from professionals. Professional maintenance personnel have rich experience and professional tools to clean, repair and replace Wood Effect Film more effectively. For example, in the decoration projects of large commercial buildings or high-end residences, regularly hiring a professional maintenance team to inspect and maintain the film can ensure the long-term stability of the decorative effect, and can also promptly discover and solve potential safety hazards. In addition, professionals can also provide personalized maintenance suggestions and plans based on actual conditions to help users better protect and extend the service life of the film, and provide users with more professional and efficient maintenance services.